When troubleshooting non-functional or poorly performing circuits, engineers can often run simulations or other analysis tools to consider the circuit at the schematic level. If these methods don't solve the problem, even the best engineers may be stumped, frustrated, or confused. I have experienced this pain too. To avoid hitting similar dead ends, let me introduce you to a simple but very important tip: keep it clean!

What do I mean by that? That said, certain materials used during PCB assembly or modification can cause serious circuit functionality problems if the PCB is not kept properly clean. One of the most common problems with this phenomenon is flux.

Figure 1 shows a PCB with excessive amounts of flux residue.

Flux is a chemical agent used to assist in soldering components to a PCB. Sadly though, if not removed after soldering, flux can degrade the surface insulation resistance of the PCB, causing serious degradation in circuit performance in the process!

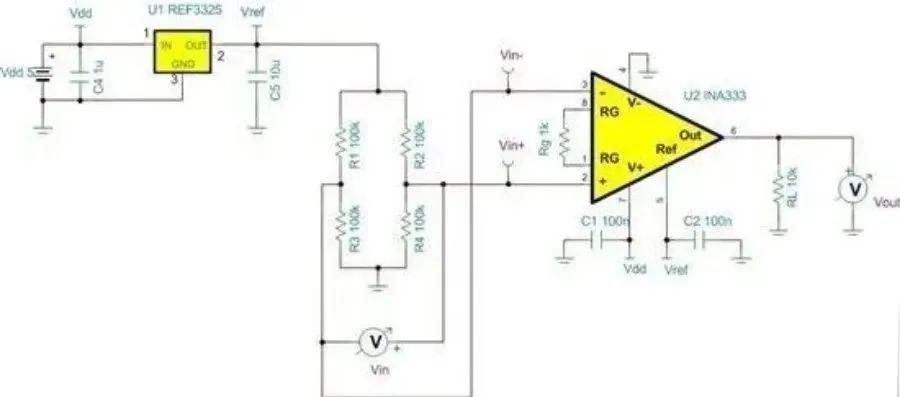

figure 2

Figure 2 is a test circuit I used to demonstrate the results of flux contamination. A balanced Wheatstone bridge network activated by a 2.5V reference voltage emulates a high-impedance bridged sensor. The differential bridge sensor outputs VIN+ - VIN- can be connected to the INA333 with a gain of 101V/V. In an ideal world, since the bridge is in equilibrium, VIN+ - VIN- = 0V. But flux contamination can cause the actual bridge sensor voltage to slowly drift over time.

In this test, after assembly, I also recorded the changes in VIN- and VOUT for one hour after different levels of cleaning:

1.Not clean;

2.Clean by hand and air dry;

3.Ultrasonic cleaning, air drying, baking.

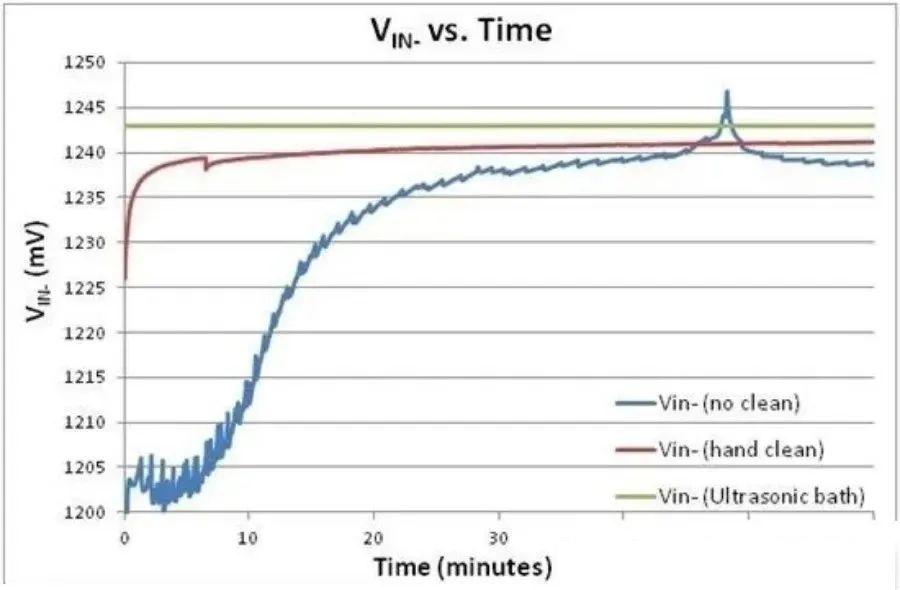

figure 3

As can be seen in Figure 3, flux contamination has a severe impact on the output performance of the bridge sensor. Without cleaning or manual cleaning, the bridge sensor voltage never reached the expected voltage of approximately VREF/2, even after a one-hour stabilization time. In addition, uncleaned circuit boards also exhibit significant external noise collection. After cleaning with an ultrasonic bath and drying completely, the bridge sensor voltage was rock solid.

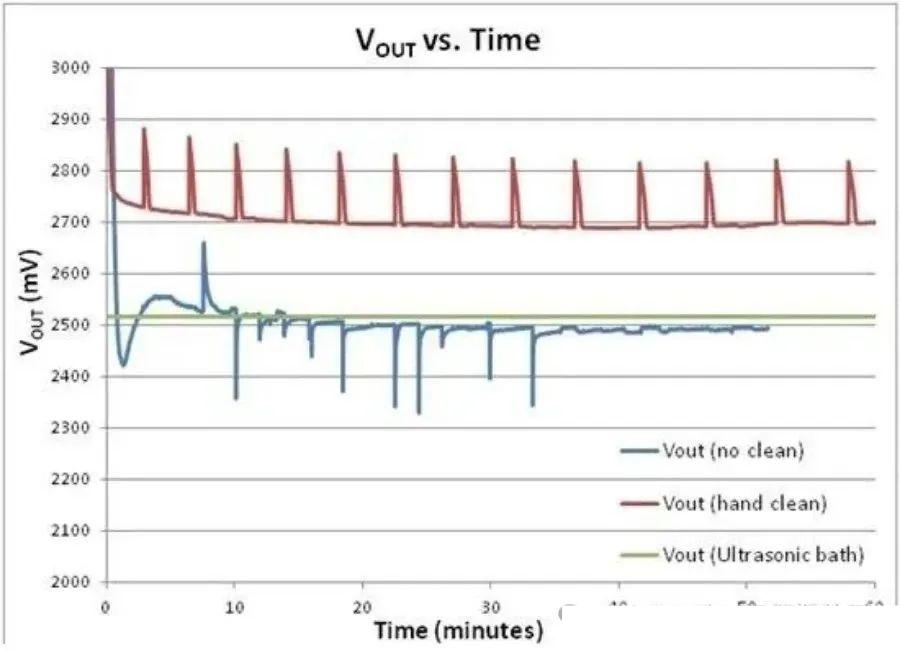

figure 4

1.Uncleaned boards exhibited DC errors, long settling times, and severe external noise pickup;

2.Manually cleaned circuit boards exhibit strange very low frequency noise. I finally found the cause - it was the air conditioning loop inside the testing facility!

3.As expected, the properly cleaned and dried boards performed extremely well, with no drift occurring at any point during the test.

In summary, improper flux cleaning can cause serious performance degradation, especially in high-precision DC circuits. As with all hand-assembled or modified PCBs, be sure to use an ultrasonic bath (or similar method) for final cleaning. Bake the assembled and cleaned PCB at a slightly higher temperature to remove any residual moisture after air drying using an air compressor. We generally bake at 70°C for 10 minutes.

This simple "keep it clean" tip should help you spend significantly less time troubleshooting and more time designing great, high-precision circuits!

Xuange Electronics is committed to becoming the world’s leading manufacturer of magnetic components, providing not only standard products but also customized design services to enable customers to achieve the best results. All materials used in the products have passed UL/CE certification and have undergone strict testing and inspection before shipment to ensure stable quality and reassure customers. It is a trustworthy long-term partner of major mainstream power supply manufacturers!

For product questions, please check the product page, you are also welcome to contact us through the contact information below, we will reply to you within 24.

https://www.xgelectronics.com/products/

William (General Sales Manager)

186 8873 0868 (Whats app/We-Chat)

E-Mail: sales@xuangedz.com liwei202305@gmail.com

(Sales Manager)

186 6585 0415 (Whats app/We-Chat)

E-Mail: sales01@xuangedz.com

(Marketing Manager)

153 6133 2249 (Whats app/We-Chat)

E-Mail: sales02@xuangedz.com

Post time: Apr-17-2024