Among the basic concepts of high-frequency transformers, there is a working state of high-frequency transformers called no-load operation of transformers.

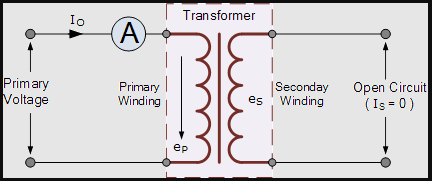

No-load operation of high-frequency transformers means that the primary winding of the transformer is connected to the power supply and the secondary winding is open, that is, there is input but no output.

In the no-load operation state, the output current of the high-frequency transformer is very small, because there is no load current passing through the transformer, and the voltage at the output end maintains a higher voltage level, which is basically the same as the voltage at the input end.

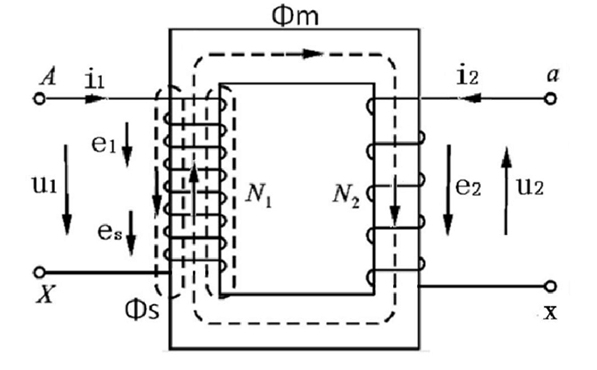

When the high-frequency transformer is no-loaded, although there is no power output at the output end, the input end still draws part of the power from the power grid, because there are iron loss and copper loss under no-load conditions.

Because of magnetic flux saturation, the hysteresis loss and eddy current loss caused in the iron core are large, especially the eddy current loss.

The resistance loss of the high-frequency transformer coil, that is, the copper loss, is small. Since the output current is very small during no-load operation, the temperature rise of the iron core and winding is very low, which helps to maintain the efficiency and reliability of the transformer.

In actual operation, it should be avoided to keep the transformer in a no-load state for a long time to reduce unnecessary energy loss and possible overheating problems.

High-frequency transformer load operation refers to the normal working state of high-frequency transformer. At this time, the input end of the high-frequency transformer is connected to the power supply, and the output end is connected to the load.

Under the load operation state, there will be current and voltage at both the input and output ends of the transformer, and the current and voltage at the input end are provided by the external power supply.

The current and voltage at the output end are adjusted according to the load requirements. The high-frequency transformer can change the winding turns ratio between the input and output ends to increase or decrease the voltage to meet the different voltage requirements of the load.

During the load operation process, the high-frequency transformer will also produce iron loss and copper loss. These losses will cause the high-frequency transformer to heat up and generate temperature rise.

Therefore, during the load operation process, it is necessary to pay attention to the temperature rise of the transformer to ensure that it operates within the safe temperature range.

Under certain circumstances, the high-frequency transformer can periodically operate at overrated current, but if the cooling system is abnormal or the insulation system fails, the transformer cannot be operated at overrated current.

Post time: Aug-10-2024