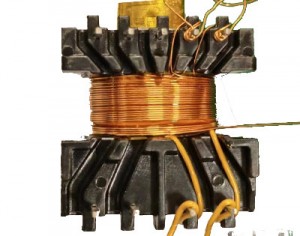

In the process of transformer winding, due to a variety of reasons, it is easy to cause the winding to fall off the layer.

So, what will transformer winding drop layer lead to? Will it blow up? For this phenomenon, how can we avoid it?

In the article “Safety knowledge of transformer”, we know the importance of creepage distance and electrical distance. In order to meet the distance requirement, we add tape and casing insulation in the transformer; for between primary and secondary, we also use retaining wall and three-layer insulated wire to meet the requirement.

Once the transformer has dropped layers, then the creepage and electrical distances between the windings will not be met. Transformer windings may be too large because of the pressure difference between the windings, and the proximity of the reason, easy to lead to the breakdown of short-circuit, so that the transformer output abnormality, can not work properly, or even directly cause the transformer burned out.

Even if the transformer does not appear abnormal for a short time, it will also have an impact on the life of the transformer. Undoubtedly, the pressure difference is too large, close to the winding, long time work will accelerate the aging of the transformer insulation material, thus affecting the life of the whole transformer.

So, in the process of transformer design and winding, how to avoid dropping layers?

First of all, for the internal winding of the transformer, should try to do the whole layer design. A lot of transformer design, often through the power engineers theoretical calculations, without the actual winding, the sample of its trial production is often handed over to the transformer factory is responsible for.

Due to the deviation of the theoretical calculation and actual winding, it is easy to appear the whole layer row is not satisfied. At this time, because the bottom of the winding is not flat, the whole layer row is not satisfied with the situation, the back of the winding winding will be easy to fall out of the layer.

Therefore, in the transformer design, for the internal winding design, try to consider the whole layer design. For really can not meet the situation, but also close to the whole layer design. Of course, the whole layer of the design should be controlled to the appropriate margin, not too loose nor too tight, to ensure that different machines winding out of the packet, are a complete layer or multi-layer.

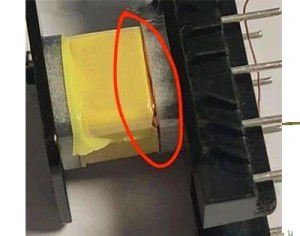

Secondly, in the case of some of the windings do not have a large number of turns, even winding is also easy to lead to drop layer. This situation exists not only in the neighboring internal windings are not arranged in the case of the whole layer, but also exists in the neighboring internal winding wire diameter is thicker, the most edge of the circle and the skeleton there is often a large gap between the case.

At this time, if the design requirements of even winding, the edge of a circle and the skeleton need to leave a certain distance between, in order to prevent completely even winding of the case, in the machine under the action of tension, the external winding of the most edge of the 1 ~ 2 turns directly into the internal winding of the edge of the gap, resulting in the fall of the layer.

In addition, the winding tape package bias, tape is too narrow, also easy to lead to the occurrence of the phenomenon of falling layer. Therefore, the process of transformer winding is particularly important.

It is worth mentioning: in the mass production process, transformer winding winding, often automatic or semi-automatic machines, fast, winding layer dropout is not easy to be detected. As a result, it is often more difficult to monitor transformer winding dropout.

In addition to ensuring the rationality of the design, the winding process of the line package, pay attention to the disassembly of the package, observe the consistency of the package, check whether the phenomenon of layer dropping occurs.

Post time: Sep-21-2024