At present, many domestic manufacturers have been involved in portable energy storage, household energy storage, industrial and commercial energy storage and other fields, and we are also laying out. Now some villages in Jiangsu, Zhejiang and Guangdong are building small-scale photovoltaic power generation, which involves household energy storage, which will be a relatively large market.

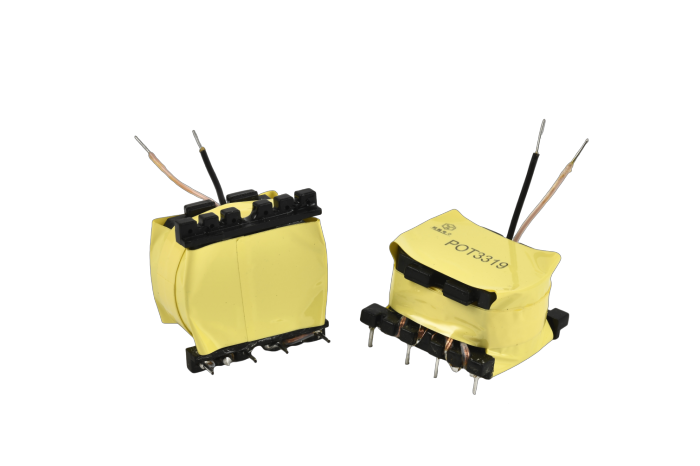

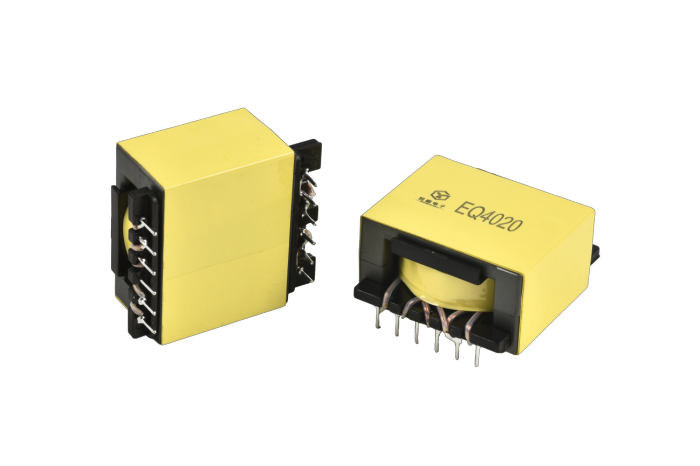

About 14 or 15 inductors and electronic transformers are used in energy storage products. The requirements for inductors and electronic transformers are high power density, high power and high frequency, and great requirements are also put forward for materials, devices, insulation materials and other aspects. High-power energy storage, such as industrial and commercial energy storage, we have participated in the development of inductors and electronic transformers for 120KW industrial and commercial energy storage, and we also have contact with portable energy storage and household energy storage, including some energy storage on the grid side. Inductance transformer in energy storage products mainly uses main transformer, resonant inductor, output filter, common mode and differential mode. At present, domestic manufacturers of inductors and electronic transformers are mainly stuck in loss, frequency range and saturation resistance. When choosing inductors and electronic transformers, manufacturers will consider the quality stability, material control, production technology, delivery inspection and so on.

Nowadays, the concentration is getting higher and higher, and energy storage head enterprises pay more attention to the overall strength of magnetic core and electronic transformer manufacturers. Because large enterprises now have the ability to invest in automated production, coupled with the high labor costs and unstable personnel, if they are small and medium-sized enterprises, there will be risks. Large enterprises can maintain product quality stability by investing in automation equipment, and there are some guarantees in all aspects of delivery, so we think that the whole machine manufacturers may pay more attention to these now. With the rapid development of new energy industry, energy storage has become another booming track.

According to the statistics of Energy Storage Leaders Alliance (EESA), in 2022, the installed capacity of new energy storage in the world was 21.3GW, up 72% compared with last year. In recent years, energy storage has been in a state of rapid growth. Under the background of “carbon neutrality”, countries are vigorously developing new energy sources, and energy storage is at the forefront. In 2023, the global energy storage industry is likely to maintain a growth rate of about 80%. Inductors and electronic transformers are mainly used in energy storage inverter modules. According to the calculation of Big Bit Industry Research Office, inductors and electronic transformers account for about 17% of the inverter cost. It is estimated that by 2025, the global market demand for energy storage inverters will be 42.8 billion yuan, and the corresponding market size of electronic transformers will exceed 7 billion yuan. At the same time, the development of energy storage also requires electronic transformers to be broadband, wide temperature, flat, high frequency and low loss. Enterprises in electronic transformer industry should pay more attention to improving the performance of magnetic materials and devices when they join the energy storage track, so that the development of magnetic materials can keep pace with the development of energy storage.

Post time: Jun-26-2023