The flashlight battery is not durable, not too long to replace the battery, which will bring a lot of trouble. Recently, an energy-saving LED flashlight was modified with a small flashlight to solve this problem. Due to the use of a dedicated LED driver integrated circuit, the original small flashlight can be slightly modified. It saves electricity, is easy to use, and has a long life of light-emitting elements. As long as it is used correctly, there is almost no need to replace the light-emitting diodes for a long time.

Working principle

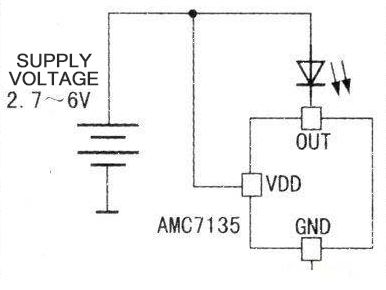

The AMC7135 is a 350mA ultra-low pressure differential current stabilizer. The AMC7135 can drive 1 ~ 3W high-power LED with a constant current output of 350mA to achieve stable brightness and increase the total output power of the battery. Its ultra-low pressure difference and low static current characteristics extend the working time of the battery. No external components are required and there is output short/open circuit protection and built-in overheat protection.

The high brightness white light-emitting diode is a new type of energy-saving lamp based on the semiconductor material gallium nitride. Its luminous intensity is 4 to 6 times that of fluorescent lamps and 15 to 30 times that of incandescent lamps, and can be used continuously for 100,000 hours, and its life is about 100 times longer than that of ordinary incandescent bulbs. The light-emitting diode with white light is higher than the light-emitting diode with other colors, generally 2.5-3.5V. When the light-emitting diode begins to work, with the increase of the current, the brightness of the light-emitting tube also continues to increase, when the current reaches 10mA, the brightness changes little, but the brightness increases more than the original dark around. Therefore, it is determined that the working current is about 10 ~ 30mA. The working principle diagram is shown in the attached figure.

led power supply manufacturers

Component selection

When purchasing LED, be sure to ask the real working voltage and working current of the LED, and observe whether the white light emitted from the top of the LED under the specified voltage and current. Some LED parameter dispersion is very large, such as its positive and negative resistance under the standard voltage LED current value deviation is large, if the price is cheap to use, it is best to measure its actual working voltage and actual working current value.

Production and debugging

Since the component has only one AMC7135 integrated block, the circuit board is not used here, but the component and the cable are directly welded and fixed in the flashlight with wax. The specific method is: after the component welding is correct, find a small flashlight (must have a larger head), weld the glass bubble of the original small electric bead with an electric soldering iron, and weld the light-emitting tube on the small electric bead base. The made circuit is installed in the head of the flashlight, so that the LED flashlight is made. It should be noted that the flashlight does not need to take out the battery for a long time to prevent battery leakage corrosion of the flashlight caused by failure.

This circuit is very simple, does not serve as any adjustment, and can be used after modification.

Articles you may be interested in:

▶Simple and practical LED light driver circuit

▶The working process of flyback isolated switching power supply

▶Why is the switching power supply using a high-frequency transformer small in size?

▶Working principle of switching power supply + circuit diagram analysis

▶LED light not working but has power repair tips

Post time: Dec-06-2024