With the increasing demand for high-power inductive transformers in the new energy market, more and more enterprises begin to pay attention to the automatic production of high-power inductive transformers. With the development of new energy market, inductance transformer is gradually developing towards high frequency, high voltage and high power. Then, will the high-power inductive transformer become the future development trend and realize mass production? To implement automatic production, what degree of automation is needed to improve quality and reduce cost?

The automatic production of high-power inductance transformer is in the initial stage. According to the national double-carbon target, in the next ten years, new energy fields such as photovoltaic, energy storage, charging piles, and new energy vehicles will remain hot markets in China, and the market demand for high-power inductive transformers will rise. Although at this stage, because most inductance transformer enterprises are only initially involved in the new energy market, customers’ demand for high-power inductance transformers is often customized and small batch, so manual production or semi-automatic production has become the first choice for enterprises producing high-power inductance transformers, and the automatic production of high-power inductance transformers is still in the initial stage. But in the long run, just like the traditional inductive transformers, the broad market demand will inevitably promote the transformation of high-power inductive transformers to automatic production. What are the requirements for enterprises to introduce new equipment inductance transformer?

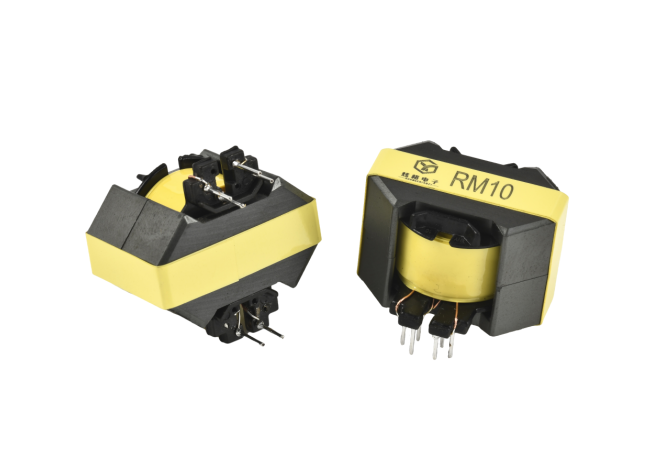

Because high-power inductive transformers are obviously different from traditional inductive transformers in performance requirements, shape and size, if inductive transformer enterprises want to take the road of automatic production, they often need to put forward new technical requirements for equipment manufacturers and introduce a batch of brand-new equipment. For example, in the winding stage, compared with the traditional inductance transformer, the high-power inductance transformer often has a large wire diameter and a large volume, which requires a winding machine with a larger wire diameter axis, and the wire diameters of high-power inductance transformers in different application scenarios are not consistent. The wire diameter of the winding machine needs to be customized according to the current requirements of inductance transformer enterprises.

Post time: May-26-2023