First, appearance test: It is necessary to have a beautiful appearance. Observe the appearance of the transformer and check whether there are any obvious abnormalities.

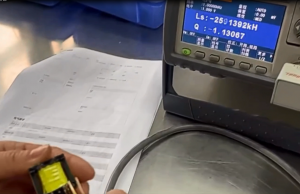

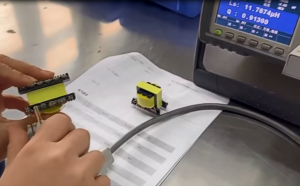

Second, inductance test:Inductance is one of the important parameters of the transformer, which determines the operating frequency, efficiency, magnetic loss, etc. of the transformer. Perform an inductance test to ensure that the inductance value is within the specified range.

Third, leakage inductance test: Leakage inductance means that part of the magnetic flux in the transformer does not pass through the main magnetic circuit, but passes through other paths, such as air, insulating materials, etc. If the leakage inductance is too large, it will have a negative impact on the performance of the transformer, so it is necessary to ensure that the leakage inductance is within the specified range.

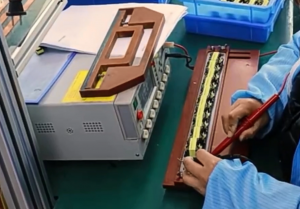

Fourth, withstand voltage test: Test the insulation performance of the equipment by applying AC or DC voltage higher than the normal working voltage to ensure that the transformer will not undergo breakdown or short circuit under normal working voltage, which may threaten personal safety.

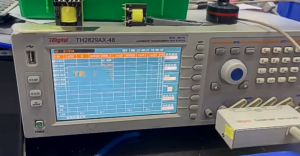

Fifth, lap test: The number of winding turns is one of the important parameters that determines the performance of the transformer. The accuracy of the number of winding turns can be detected through the turn number test to ensure that the transformer is working with the correct number of winding turns. After these tests, we in Bozhou will package and ship the qualified products.

We have 15 years of experience in producing high frequency transformers. All products have passed UL certification, ROHS testing, and have been tested and screened at all levels to ensure product quality. All materials and workmanship of the transformer comply with UL safety regulations.

We also provide a 5-year product warranty, allowing you to shop worry-free and with guaranteed quality!